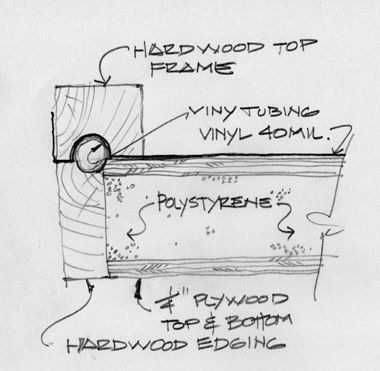

I wasn't very clear in my verbal description, Rog. Here's a sketch of the assembly:

See ""

As you can see, the foam sheet is sandwiched between the two sheets of plywood with the hardwood frame around it all. In reality the foam is closed cell so does have a moderate amount of compressive strength.

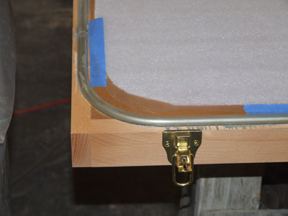

The best adhesive I found for bonding the vinyl tubing to wood inside the lower groove was Alcoa aluminum gutter seal. I taped the 40mil sheet to the outside of the upper frame with gorilla tape and hinged it at the back.

See ""

The vinyl tubing provides a great seal -

See ""

These are a few of the panels I've gotten done thus far:

See ""

The larger ones are actually pairs of doors I laid up as a single sheet to get a continuous grain match across both doors.

Now the fun begins ....

See ""